I make these lamps from reclaimed scrap wood and by melting down single-use plastic cups to form the panels. Each lamp has its own character, sometimes showing the age and life of the wood, sometimes the colors in the panels swirl with a hint of a mermaid or other logos that had been on the old cups.

It takes between 25 and 50 plastic cups to make one lamp. The idea to use plastic cups was originally just that, an idea, and we never expected the panels to be as gorgeous as they are; the final product loos and feels like mica or other minerals, and even the ink from company logos and and artwork on the cups becomes a swirling, organic mix of found art.

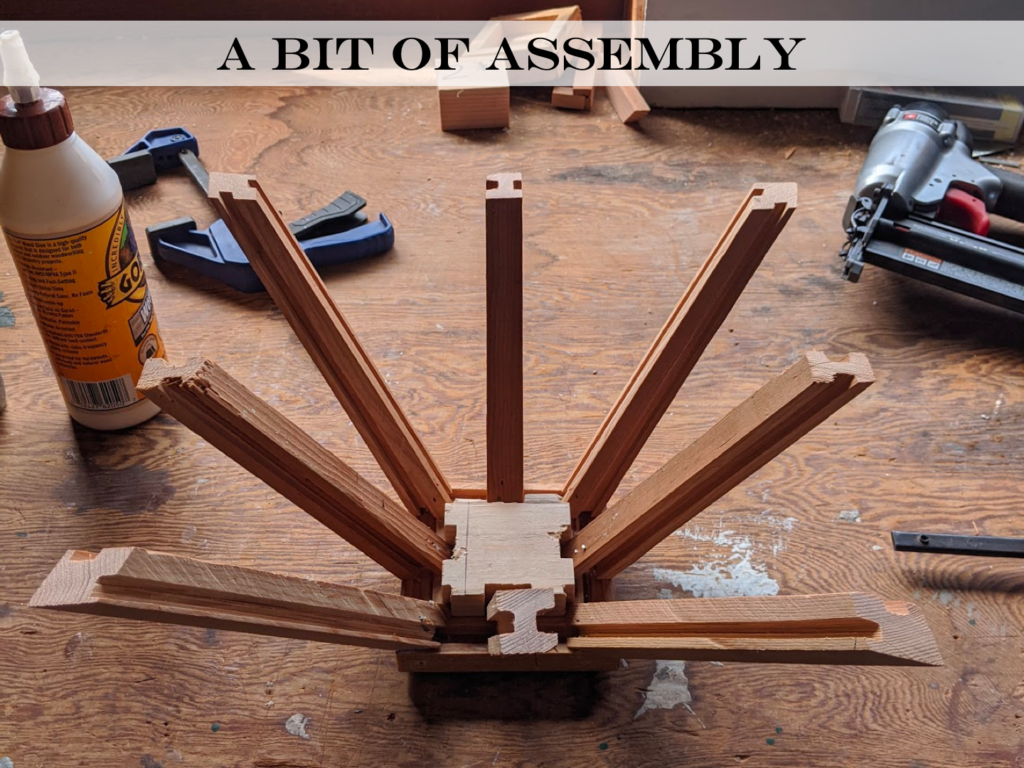

The frames are made from reclaimed lumber, some from our own remodel projects, some gathered from friends, but all wood that would otherwise end up in the landfill. The wood retains its character, sometimes showing the old nail holes, or minor cracks where the sap ran out years ago, and sometimes old wallpaper or nails may show through, giving each lamp its own identity and interest.

There’s something very satisfying about combining the skills of materials science (melting and forming polypropylene cups into panels), carpentry (there’s a lot of math in a pyramid), and electrical wiring (all electrical parts are new to ensure safety). While we know we have a nearly impossible problem grappling with our single use plastic consumption, it’s also nice to know that each lamp is keeping just some of that plastic out of the waste stream, and out of the envorinment.

You can buy these lamps directly from this website, or contact me directly to learn more.